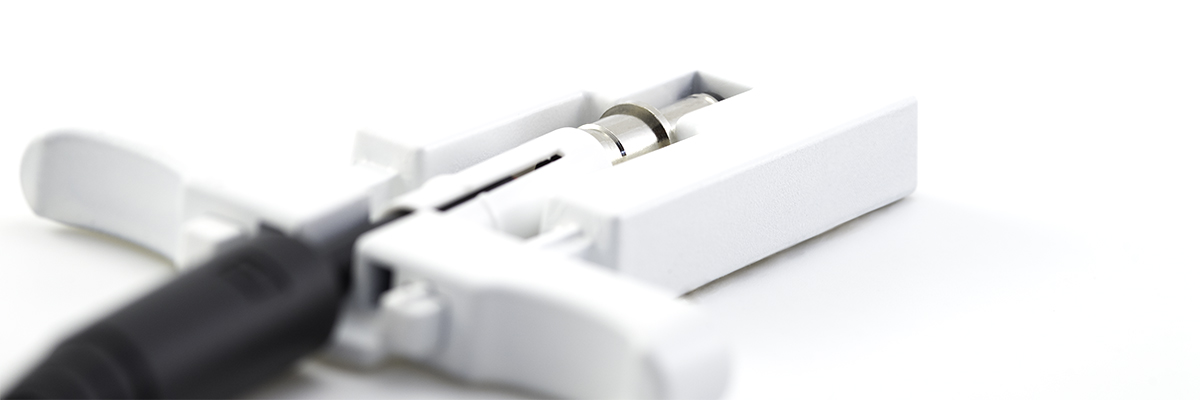

Tensility launches its Assembly Type Connector design for a production look and faster installation. Once assembled, the final product looks like a finished molded cable. The connector includes a snap-on inner sleeve that is easily assembled with Tensility’s custom-designed hand tool. The outer sleeve accommodates a range of wire gauges with an adjustable strain relief. An instructional video, PDF, and downloadable 3D model are provided through Tensility for a simple assembly.

Assembly Type Connectors are available in a 5.5 mm outer diameter with spring contacts in 2.1 mm and 2.5 mm center pin sizes, and they can accommodate outer wire diameters of 2.4 mm to 5 mm. These connectors are rated at 48 V and have current ratings of either 6.0 A or 7.0. All parts needed for assembly are available through Digi-Key and Arrow Electronics. The hand tool is also available for purchase at these distributors, and a free downloadable 3D model is available on Tensility.com. Custom configurations are available directly through Tensility.

SEE ALL DC ASSEMBLY TYPE CONNECTORS TENSILITY OFFERS

Key Features |

Applications |

|

|

|

Round wire Ø2.4 – 5.0 mm ( 0.1 – 0.2 inches), 18 AWG or smaller recommended

For nickel plated connectors, we recommend using a good quality flux to aid in soldering and improve joint strength. We have found Kester 985M Flux to be a good product in these situations. Without using flux to prepare the surface, nickel plating may cause cold solder joints or result in a damaged connector from overheating during soldering.